Toqua helps Vroon leverage sensor data to break free from sea trial-based performance modeling

Toqua and Vroon have been working together since 2022.

As more and more companies are targeting short-term efficiency gains to reach their decarbonization targets, sensor data is becoming commonplace in the maritime industry. Still, applications that actually capture the value of this data remain rare. Because of this, traditional sea trial-based performance models - and their limitations - remain the norm. These model limitations hinder performance experts from realizing efficiency gains.

The limitations of sea trial-based modeling

Sea trial documents aim to describe the performance of a vessel at new-build. This data is generated during ‘sea trials’ when the newly constructed vessel is tested and measured for several operating conditions. The main purpose of this exercise is to validate if the actual performance of the vessel after construction meets the contract performance promised before construction. And for that purpose, sea trials are functional.

Unfortunately, the industry also uses sea trial data to analyze the operational performance of vessels. And sea trial curves are not suited for that purpose. Sea trial curves are made to analyze the newbuild performance of a vessel when brand new, and only for limited design drafts, design speeds, and ‘good weather’ conditions. However, for operational performance monitoring, you need to be able to analyze all possible drafts, all possible speeds, and all possible weather conditions, while also accounting for the vessel’s hull performance changing over time.

Main limitations of traditional sea trial-based models:

- Limited to design drafts

- Limited to design speeds

- Limited to ‘good weather’ conditions

- Do not account for vessel performance changing over time

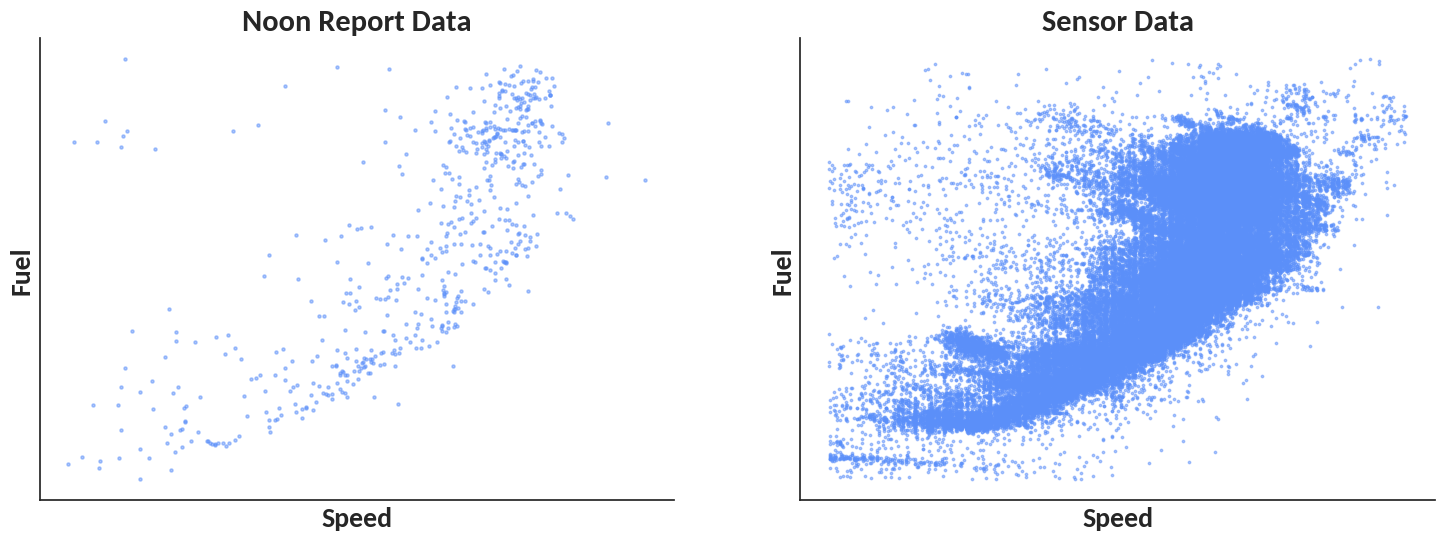

The industry has tried to overcome these limitations by drawing on operational noon report data and heavy filtering combined with formula-based correction factors (ISO 15016, ISO 19030). Unfortunately, noon reports are riddled with inaccuracies, leading to inaccurate models. And heavy filtering does not solve the problem; it ignores it. Finally, theoretical formulas frequently don’t perform well in practice as they require extensive ship particulars that are often unavailable (source). As a result of the above limitations, the goal of accurate models for all operational conditions remains unachieved.

How sensor data helps overcome these limitations

With sensor data, there’s suddenly an abundance of reliable, high-frequency data, for all possible operating conditions. A massive opportunity to overcome the limitations of traditional models.

But sensor data only becomes valuable when used in the right way. Lots of big data by itself is not actionable; it’s even confusing or overwhelming. As a result, many companies today are collecting sensor data, storing it somewhere, but not using it. A missed opportunity. And that’s where Toqua enters the picture.

Toqua's solution: Ship Kernels

Toqua has developed a proprietary modeling technique based on physics-informed machine learning, that captures the value of this sensor data to create next-generation speed-fuel models: Ship Kernels. These Ship Kernels can model a ship’s performance for all speeds, all drafts, all weather conditions, while also automatically updating over time as vessel performance changes. These models are a game-changer compared to restrictive sea trial-based models.

The results for Vroon

The implications of having better models like these cannot be underestimated. Speed-fuel models lie at the heart of basically every single decision taken in shipping. Moving from 10%-20% inaccuracy using traditional models, to only a few percentage points of inaccuracy using Ship Kernels, is a real game changer for all operational decision-making.

In the right hands, these sensor-based models can drastically improve decision-making such as:

- What speed & consumption can we warrant in our commercial discussions?

- Are we still performing as promised?

- When to schedule a hull cleaning?

- How effective was the hull cleaning?

- What was the effect of dry-docking?

- What’s the impact of the new paint?

- What are the actual operational savings of the newly fitted Energy Saving Device?

- What speed & consumption can we use for commercial voyage simulations in our VMS?

- How can we predict emissions of future voyages in different scenarios?

This enables more constructive CII discussions and more flexible dealmaking. - What route should we sail, given current weather conditions?

See Euronav case: Euronav finds Toqua's models could double weather routing fuel savings - etc.

Conclusion

Like many shipping companies today, Vroon’s ship performance experts were constrained in their analysis due to the limited reliable data available: sea trial curves and noon reports. Collecting operational sensor data opened up new possibilities. Together with Toqua’s technology, they captured the potential of this big data by creating highly accurate & flexible ship performance models (Ship Kernels). These models have shown great promise to reduce emissions and fuel costs, while also empowering in-house performance experts to map their decarbonization strategy in a data-driven way.